|

|

---- ----

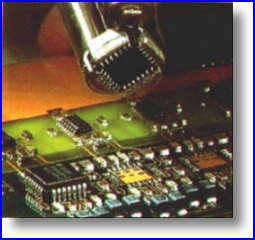

Complete line of Fine Pitch, High Speed SMT placement machines.

BGA placement capable

* Juki FS730 High Speed Flexshooter

* Juki FM760 Fine Pitch Flexmounter

*

Juki 2020 Fine Pitch Flexmounter

*

Juki 2050 Fine Pitch Flexmounter

* X-Ray BGA Inspection station

----------- -----------

*

Heller 1500, 10 zone reflow oven

* Heller 1500, 10 zone reflow oven

with edge rail

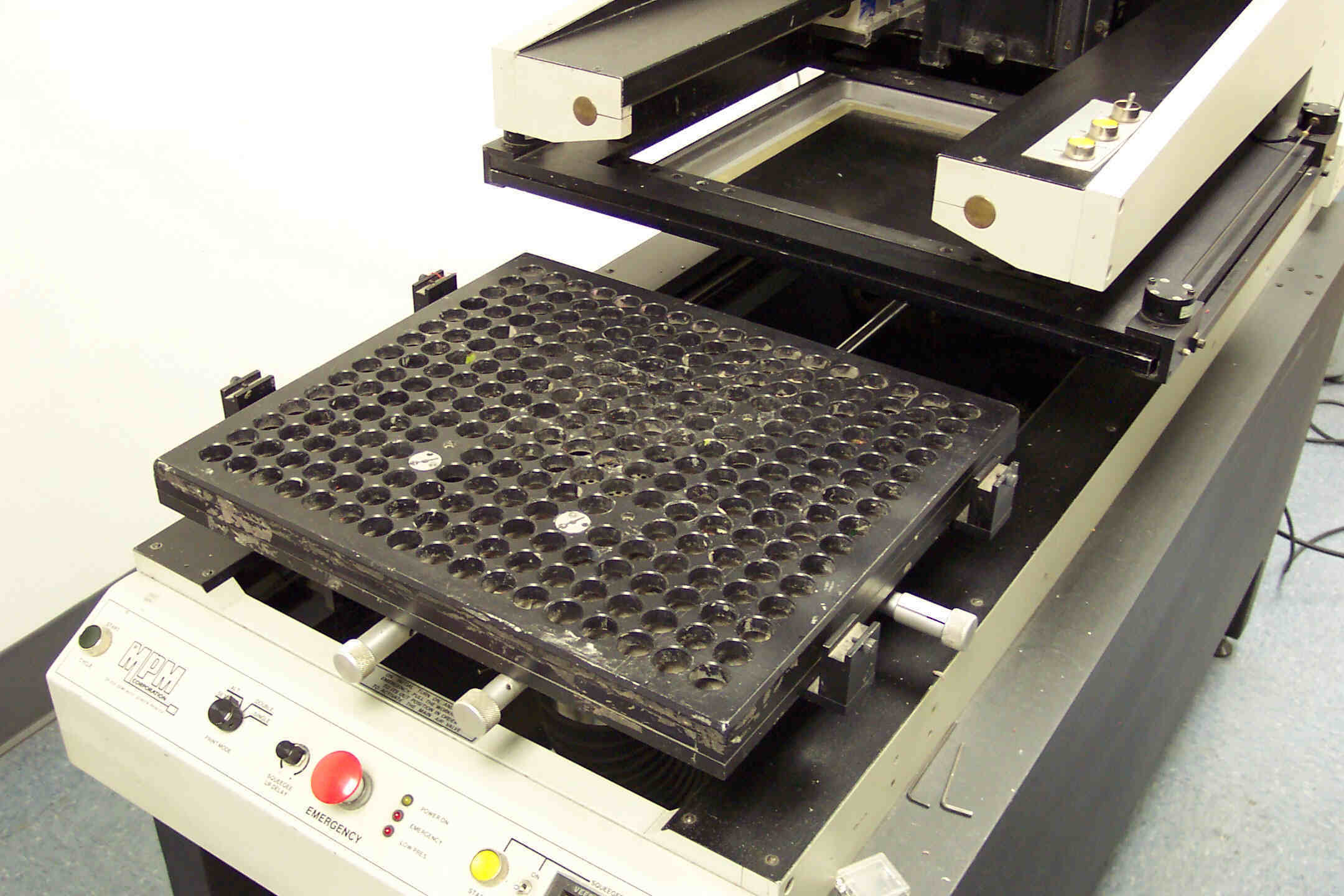

* MPM SPM semi automatic screen printer

*

Surface Mount Technique Manual Screen Printer

-- --

Our Through-Hole equipment is designed for high volume PCB assembly, using:

*

Electrovert Econopak II SMT with SMT chip Wave for bottom side solder.

*

Electrovert Econopak II SMT with SMT Wave for LEAD FREE

*

Hollis Aquastation In-line cleaner.

* Q-Corp LOM-II mass lead trimmer.

Flow Solder Equipment

In-Line cleaner

using De-ionize water treatment center

A.P.E. Chipmaster SMD-1000 rework station.

Our standard workmanship is performed per IPC-610 class II or III

as defined by our customer requirements.

ESD (Electro Static Discharge) programs insure customer products

are handled to minimize static charge failures.

Ten station push lines are designed for fast Thru-Hole assembly of Ten station push lines are designed for fast Thru-Hole assembly of

your product. 3-D microscopes are used for complete inspection

of solder quality and workmanship.

Functional as well as computerized test on customer's products available!

All in all SAS Manufacturing has the equipment, knowledge and

resources to build your product right the first time... all the time.

Give us a call for a competitive quote on all of your SMT

or Thru-Hole assembly requirements.

951-734-1808 Phone

951-734-4581 FAX

|

SAS Manufacturing, Inc.

SAS Manufacturing, Inc.

SAS Manufacturing, Inc.

SAS Manufacturing, Inc.

![]() 405 N. Smith Ave Corona, CA. 92880

405 N. Smith Ave Corona, CA. 92880